1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

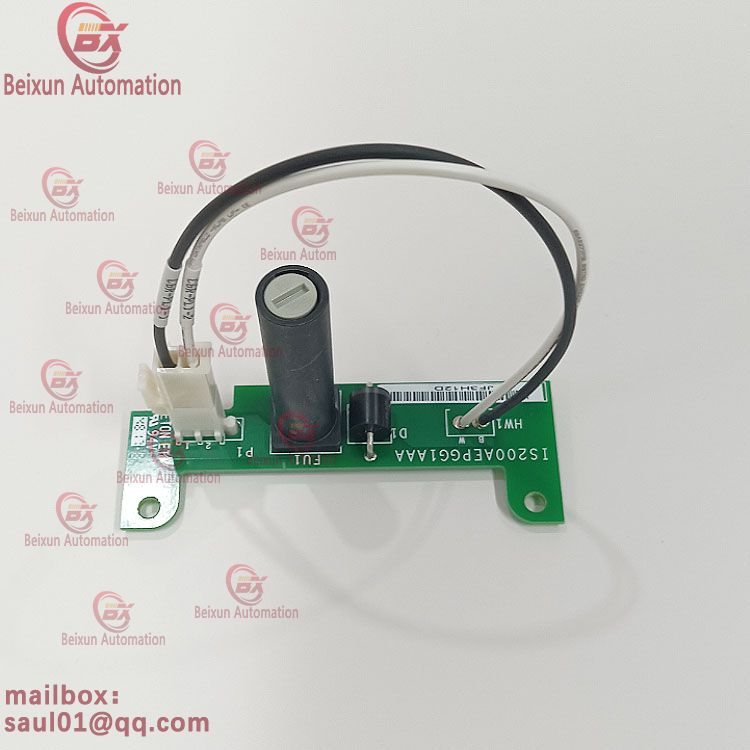

GE IS200AEPGG1AAA Drive Control Circuit Board: Industrial Drive Management Core

The GE IS200AEPGG1AAA is a drive control circuit board designed for GE's Mark VIe control system, specializing in industrial motor drive management and turbine control applications. As a key component in power generation and heavy machinery automation, it ensures precise control over drive systems while withstanding harsh industrial environments.

Technical Specifications & Design

Series Compatibility: Specifically engineered for Mark VIe systems, integrating with GE's Speedtronic turbine control platforms.

Form Factor: Standard PCB design with dimensions approx. 300mm × 200mm, optimized for rack mounting in control cabinets.

Power Supply: 24V DC (backplane-powered) with surge protection, consuming ~5W under full load.

Temperature Range: Operational: -40°C to +70°C; Storage: -45°C to +85°C, suitable for extreme industrial conditions.

Certifications: Compliant with CE, UL, and EMC standards (EN 61000-6-2/4), ensuring safety and electromagnetic compatibility.

Core Functionalities

1. Drive Control Architecture

Motor Regulation: Manages AC/DC motor drives for speed, torque, and position control in turbines, pumps, and conveyors.

PWM Generation: Produces pulse-width modulation signals to drive power electronics (e.g., IGBTs, thyristors) with precision.

Fault Protection: Integrates overcurrent, overvoltage, and overtemperature protection circuits to prevent drive system damage.

2. Communication Interfaces

Serial Links: RS-485/422 ports for real-time data exchange with PLCs, HMIs, and SCADA systems (up to 1 Mbps).

Parallel Interfaces: Connects to I/O modules (e.g., IS200AEPAH1AHD) for analog/digital signal processing.

Proprietary Protocols: Supports GE's drive control protocols (e.g., Speedtronic) for seamless system integration.

3. Signal Processing

Analog-to-Digital Conversion: 12-bit ADC for monitoring drive parameters (current, voltage, temperature).

Digital Filtering: Onboard DSP (digital signal processor) reduces noise in high-interference environments.

Encoder Interface: Reads position feedback from incremental/absolute encoders for closed-loop control.

Hardware Components

Microcontroller: High-performance MCU (e.g., Texas Instruments DSP) for real-time control algorithms.

Power Conditioning ICs: Regulates voltage and protects against transients from industrial loads.

Optocouplers: Isolates control signals from high-voltage drive circuits, enhancing safety and reliability.

LED Indicators: Displays status for power, communication, and fault conditions (e.g., green for normal, red for errors).

Connectors: Sealed terminals for field wiring (e.g., motor leads, sensor inputs) and backplane communication.

Industrial Applications

1. Power Generation

Turbine Drive Systems: Controls steam/gas turbine generators, adjusting speed to maintain grid frequency stability.

Wind Energy: Manages pitch and yaw drives in wind turbines for optimal energy capture.

2. Manufacturing & Heavy Industry

Conveyor Systems: Regulates motor speed in mining, paper, and steel plants for material handling.

Pump & Compressor Control: Adjusts drive torque for water treatment, oil pipeline, and HVAC applications.

3. Marine & Aerospace

Propulsion Systems: Controls ship engines and aircraft ground support equipment driv

GE IS200AEPGG1AAA Drive Control Circuit Board

GE IS200AEPGG1AAA Drive Control Circuit Board

GE IS200AEPGG1AAA Drive Control Circuit Board

You can also learn about these:

GE power board DS200DCFBG1BKC DC feedback module

GE IS210AEBIH1BED gas engine module

GE UCSCH1 IS420UCSCH1A controller

GE 029.38089607 control module