1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

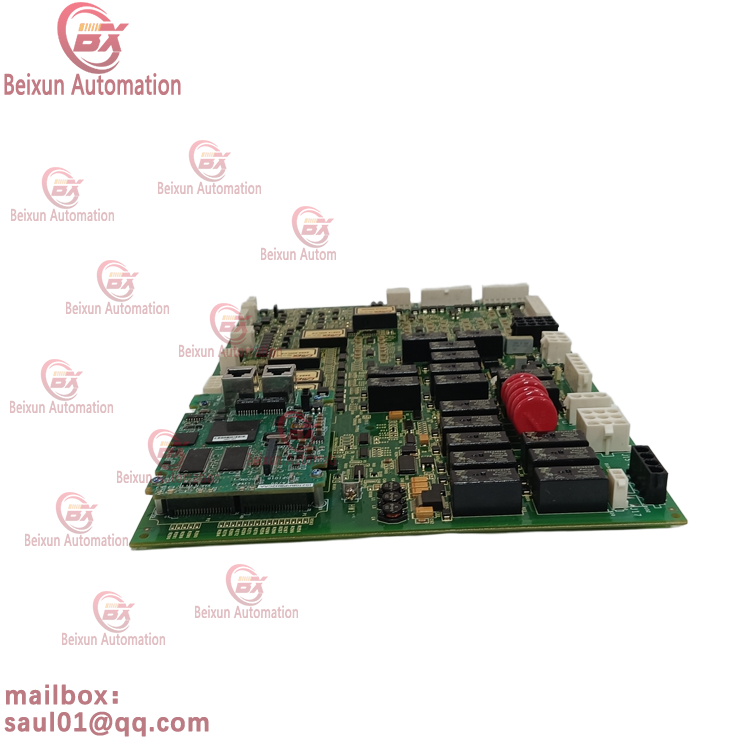

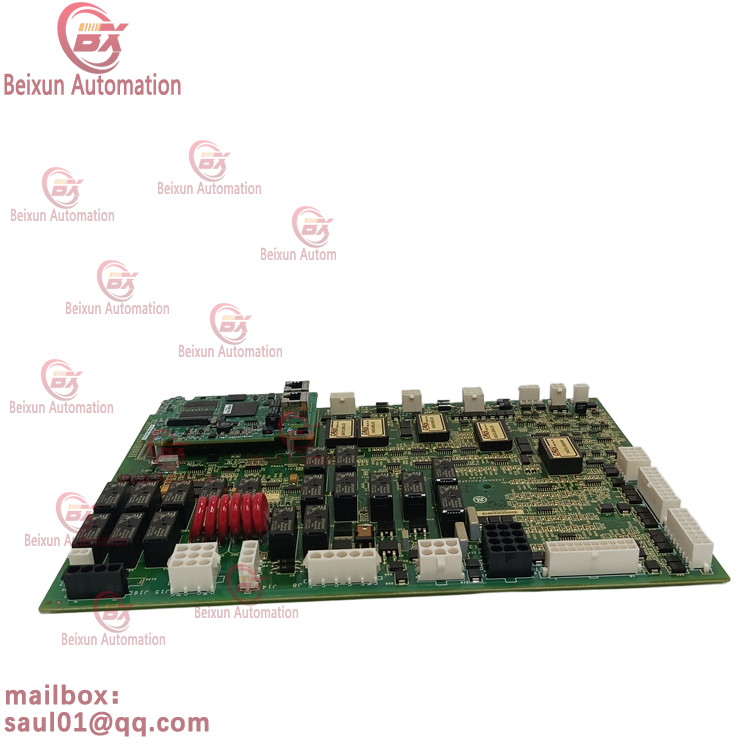

GE IS210BPPBH2CAA Turbine System Module Details

I. Product Positioning and Core Functions

GE IS210BPPBH2CAA is a high-performance control module specially designed for turbine system, which is commonly used in gas turbine, steam turbine and other industrial turbine control systems. As the “nerve center” of the system, it undertakes the core tasks of data processing, signal transmission and precise control. It accurately regulates the turbine operation state through real-time acquisition of key parameters such as rotational speed, temperature, pressure and so on during turbine operation, and after rapid processing by built-in algorithms, ensures that the turbine maintains high efficiency and stable operation under complex working conditions, and at the same time realizes the abnormal state early warning and fault diagnosis, so as to enhance the safety and reliability of the turbine system.

Core performance advantages

(I) High-speed data processing capability

Equipped with advanced multi-core processor, it has extremely high data processing speed, and can process millions of commands per second, which can respond to the rapidly changing working condition data during the turbine operation in real time. In the turbine's rapid startup, sudden load changes and other complex conditions, it can quickly analyze the massive data collected by the sensor and quickly generate control instructions to adjust the turbine's operating parameters, avoiding performance degradation or failure due to response delays.

(ii) Precise control and adjustment

The built-in high-precision control algorithm can realize precise adjustment of key parameters such as turbine speed, air intake, fuel supply and so on, according to the different stages of turbine operation and the demand of working conditions. Through the closed-loop control mechanism, the actual turbine operating parameters are compared with the preset target parameters in real time, and the control strategy is dynamically adjusted to ensure that the turbine always operates in the optimal efficiency zone, effectively reducing energy consumption and improving energy utilization efficiency.

(iii) Powerful communication compatibility

Supporting a variety of industrial communication protocols, such as Modbus, Profibus, Ethernet/IP, etc., it can seamlessly communicate with all kinds of sensors, actuators, monitoring systems and other control modules in the turbine system. Whether it is the interconnection of equipment in close proximity or remote monitoring in long distance, it can ensure stable and fast data transmission and realize the integrated control and remote operation and maintenance management of the turbine system.

(D) High reliability and stability

Adopting industrial-grade electronic components and anti-interference design, it has excellent anti-electromagnetic interference, high-temperature and vibration resistance, and can adapt to extreme temperature environments ranging from - 40℃ to 85℃, and harsh industrial scenarios such as strong vibration and high dust. At the same time, with redundant design function, when the module fails, the redundant module can be automatically and seamlessly switched to ensure the continuous and stable operation of the turbine system, significantly reducing the risk of downtime due to module failure.

Technical Parameters

Parameter category Specific parameters

Model IS210BPPBH2CAA

Applicable systems GE turbine control systems (such as Mark VIe, etc.)

Processor type Multi-core high-performance industrial-grade processor

Data processing speed ≥500MIPS

Communication interface RS-232, RS-485, Ethernet interface (support multiple protocols)

Operating temperature range -40℃ - 85℃

Storage temperature range -45℃ - 90℃

Power input 24VDC (±10%)

Size 180mm×120mm×50mm

Weight Approx. 1.2kg

Protection class IP40

Application Scenarios

(I) Power generation field

In gas turbine power plants and combined cycle power plants, IS210BPPBH2CAA module monitors the operating status of gas turbines in real time and precisely adjusts the fuel supply and air intake to ensure the maximization of power generation efficiency. At the same time, it is linked with the monitoring system of the power plant to realize remote monitoring and centralized management of power generation equipment and ensure stable power supply.

(II) Petrochemical industry

It is used for controlling steam turbine drive equipment in petroleum refining and chemical production processes, precisely adjusting the speed and power output of steam turbines to meet the power requirements of different production processes. In the complex chemical production environment, it guarantees the long-term stable operation of the turbine system by virtue of its high reliability and anti-interference ability, and helps the production process to proceed continuously and safely.

(III) Aerospace ground test

In the aerospace engine ground test platform, the module can collect real-time engine operation data, accurately control the parameters of the test stand, simulate the engine operation state under different flight conditions, and provide accurate data support and reliable control guarantee for the aerospace engine performance test and optimization.

GE IS210BPPBH2CAA turbine system module

GE IS210BPPBH2CAA turbine system module

GE IS210BPPBH2CAA turbine system module

You can also learn about these:

GE power board DS200DCFBG1BKC DC feedback module

GE IS210AEBIH1BED gas engine module

GE UCSCH1 IS420UCSCH1A controller

GE 029.38089607 control module