1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

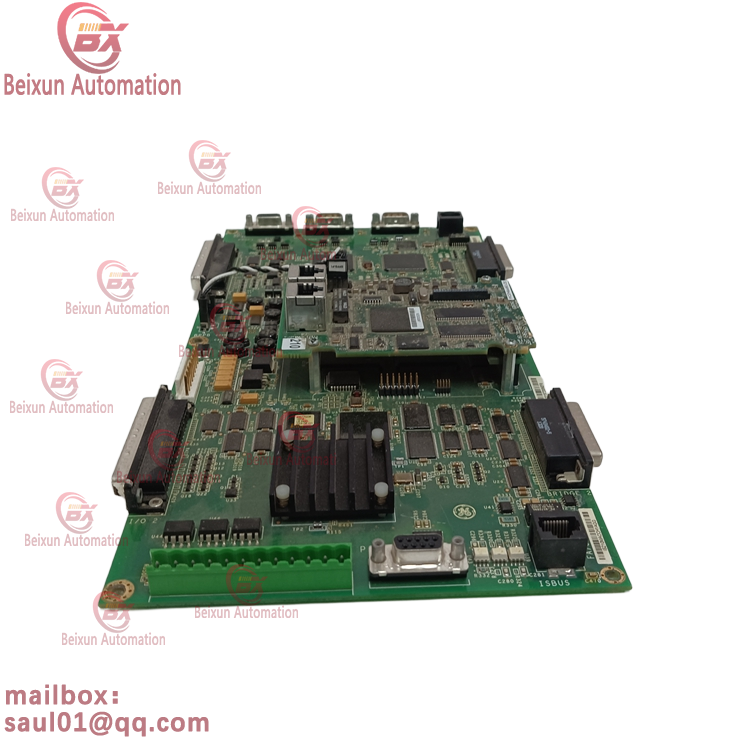

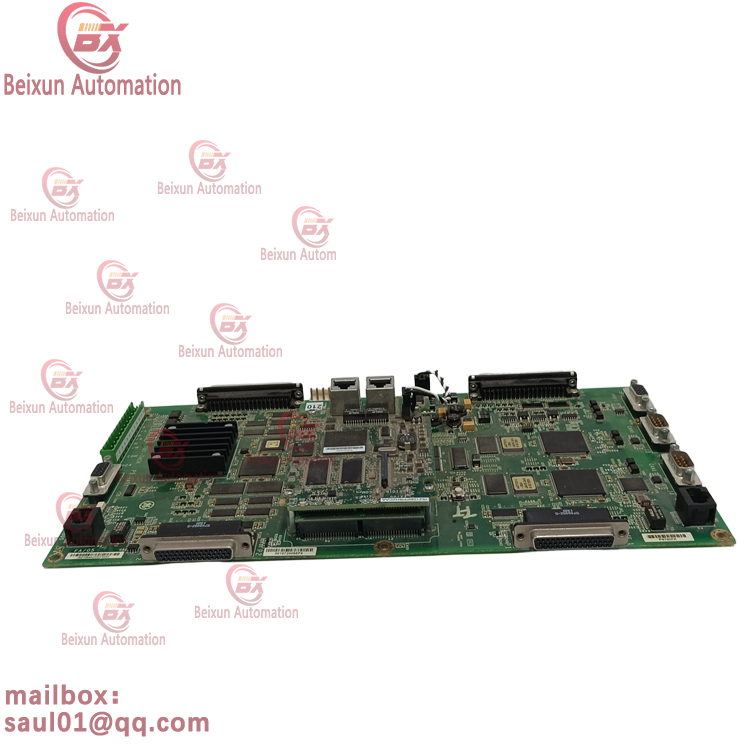

IS210MACCH1AGG Details

I. System and Application

IS210MACCH1AGG is a key component of General Electric's (GE) Mark VIe control system, designed to meet the needs of high-performance control and data processing in harsh industrial environments. It plays a central role in the operation and control of gas and steam turbines, accurately executing all kinds of complex control algorithms to ensure the efficient and stable operation of turbines; in the automated production process of oil and gas field, it can reliably control the related equipments; and in the smart grid architecture, it can help to realize the accurate distribution of power and effective management of loads.

Performance Characteristics

(A) High-performance processing power

High-efficiency embedded processor: Equipped with a powerful embedded processor with fast computing speed, it can quickly process a large amount of complex data, easily execute various types of complex control algorithms, and ensure that the system responds quickly and accurately to changes in various working conditions. For example, it can adjust the control parameters in real time during the rapid speed-up and speed-down processes of the gas turbine.

Multi-task operation support: With excellent multi-task processing capability, it can run multiple tasks simultaneously to meet the demand for synchronized processing of multiple parallel tasks in large-scale industrial control systems, such as steam turbine speed control, temperature adjustment, pressure monitoring, etc., and improve the overall operation efficiency of the system.

(ii) Modularized design

Plug-in convenient installation: The plug-in design makes it possible to quickly and conveniently plug and unplug modules during system installation, maintenance and function expansion, which greatly shortens downtime and reduces maintenance costs.

High compatibility integration: Seamless integration with GE Mark VIe system, both in terms of electrical interfaces and communication protocols, has a high degree of compatibility, which ensures the stable and efficient operation of the entire control system, and avoids system failures caused by compatibility problems.

(iii) Industrial-grade reliability

Selection of high-quality components: in the selection of components, strict compliance with industrial standards, the selection of high-quality electronic components, these components are processed through a special process, with excellent resistance to high temperature, vibration, and anti-electromagnetic interference, can be in the high temperature, high humidity, strong electromagnetic interference and other harsh industrial environments such as long time and stable work.

Redundancy function guarantee: designed with redundancy function, when a key component fails, the redundant components can be immediately and seamlessly switched into operation to ensure continuous operation of the system, avoiding single point failure leading to paralysis of the entire control system, effectively improving the reliability and availability of the system.

(D) Communication and interface support

Rich communication protocol support: supports a variety of commonly used communication protocols, such as Ethernet, RS-232, RS-485 and so on. Through the Ethernet interface, high-speed and long-distance data transmission can be realized, which is convenient for communication and networking with the host computer and other intelligent devices; RS-232 and RS-485 interfaces can meet the communication interface requirements of different devices and ensure stable communication with various types of sensors, actuators and other devices.

High-speed data transmission: with high-speed data transmission capability, fast data transmission rate and low delay, it can ensure that the control commands are issued to the actuator in time, and the monitoring data are fed back to the control system in real time, which can provide strong support for the real-time control of the system, and improve the system response speed and control accuracy.

(E) Diagnosis and fault management

Integrated self-diagnostic function: It integrates a powerful self-diagnostic function, which can detect its own hardware status and operation program in real time. Once abnormalities are found, it can quickly and accurately locate the fault point and generate a fault report in a timely manner, providing a basis for maintenance personnel to quickly investigate and solve the problem.

Remote monitoring and fault analysis: Support remote monitoring, with the help of network communication, the maintenance personnel can view the real-time equipment operation status and fault information in the remote control center. At the same time, the system also has a fault analysis function, which can analyze the historical fault data, excavate potential faults, and take preventive measures in advance to reduce equipment downtime.

Technical Parameters

Parameter Description

Model IS210MACCH1AGG

Purpose Data processing and control

Compatible system GE Mark VIe control system

Processor type High-performance embedded processor

Communication interfaces Ethernet, RS-232, RS-485, etc.

Power requirements Industry standard input voltage

Operating temperature range -30°C to 70°C

Immunity Complies with industrial EMC standards

Installation Plug-in installation, suitable for standard racks

Diagnostics Real-time status monitoring, self-diagnostics and alarms

GE IS210MACCH1AGG Communication Interface Module

GE IS210MACCH1AGG Communication Interface Module

GE IS210MACCH1AGG Communication Interface Module

GE IS210MACCH1AGG Communication Interface Module

GE IS210MACCH1AGG Communication Interface Module

You can also learn about these:

GE power board DS200DCFBG1BKC DC feedback module

GE IS210AEBIH1BED gas engine module

GE UCSCH1 IS420UCSCH1A controller

GE 029.38089607 control module