1.Warranty time: 1 year

2.Delivery time: 3-5 days

3.Product quality: new or discontinued second-hand

1. We are a global trading company, we have a large stock of spare parts, we also produce energy storage batteries

2. Our main sales products are industrial automation control equipment accessories, such as: controller board, processor module, communication module, input and output module, power module (various circuit boards and cards), touch screen, servo driver, servo motor, sensor, cable......

3. We can not only provide new products, but also supply cold and discontinued spare parts, all the discontinued parts will go through strict testing to ensure the reliability of product performance, so that customers can buy and use at ease

4. For more information, please contact us: Contact: Amy | Email: saul01@qq.com | Tel(WhatsApp/Wechat): +86-15359298283

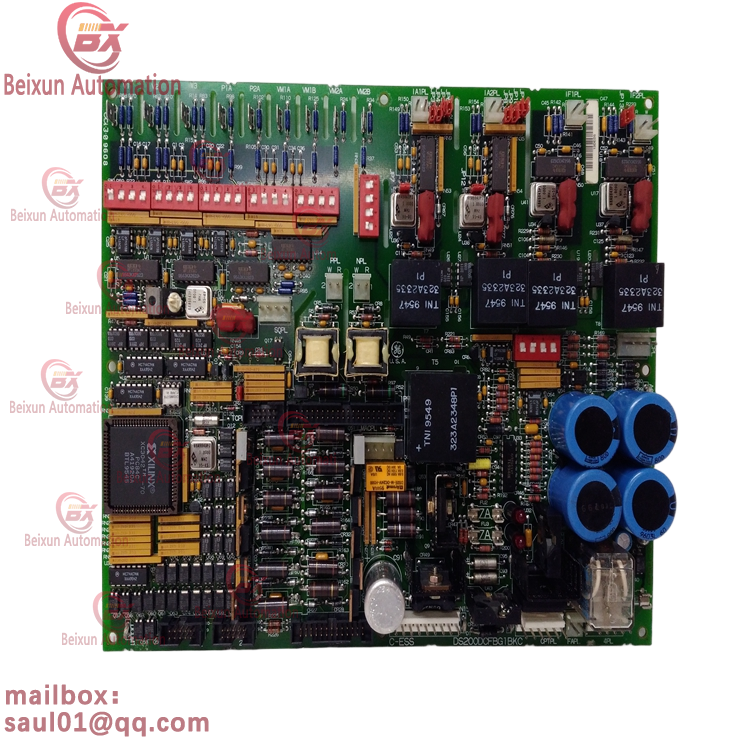

GE Power Board DS200DCFBG1BKC (DC Feedback Module) - English details

Core functions:

DC Feedback: The core role of this module is to monitor, regulate and feedback the voltage and current status of the critical DC power bus in the gas turbine or steam turbine control system (mainly Mark V series).

Status signal provision: It converts the monitored DC power status (normal/abnormal) into a digital signal for the main controller (such as Mark V's <ICRH> processor) or protection system.

Protection function support: its feedback information is an important basis for the system to judge whether the power supply is healthy and whether the relevant protection (such as overvoltage, undervoltage, and overcurrent protection) is triggered.

Main uses:

This module is an integral part of the GE Mark V Speedtronic turbine control system.

It is usually installed on the I/O or auxiliary power board of the DS200 series (such as DS200 TBCI, DS200 DAP, DS200 LAP, DS200 SHMC, etc.).

It is mainly used to monitor:

+125 VDC bus: main control power supply.

+/ -15 VDC bus: provides power to analog circuits such as operational amplifiers on the control board.

+/ -50 VDC bus: sometimes used for special I/O or drive circuits.

Ensure stable and reliable DC power supply to the control system, and timely alarm or trigger shutdown protection when the power is abnormal.

Key features:

Multi-channel monitoring: A module usually contains multiple independent monitoring channels for simultaneous monitoring of different DC voltage levels (such as +125V, +15V, -15V, +50V, -50V).

Threshold detection: The internal circuit sets a precise voltage threshold (overvoltage point, undervoltage point) and a possible current threshold (overcurrent point). When the monitored values exceed these thresholds, the module changes its output state.

Isolation and signal conditioning: converts high-voltage DC signals into low-voltage logic signals safely and provides electrical isolation to protect low-voltage control systems.

LED indicator: There is usually LED indicator on the module, which is used to display the status of each monitored power supply (such as green constant light/off when normal, red/off/flashing when fault), so as to facilitate rapid on-site diagnosis.

Digital Output Signal: A digital signal (usually dry contact or TTL level) that outputs the power status (OK/Fault) to the master controller or protection logic.

Technical parameters (typical) :

Monitoring voltage range: covering +125VDC, +/-15VDC, +/-50VDC and other typical turbine control power supply.

Input power supply: The working power supply (such as +5VDC, +/-15VDC) is usually provided by the motherboard (such as DAP, TBCI) on which it is located.

Output signal: digital status signal (fault/normal).

Operating temperature: conforms to industrial standard (usually 0°C to +70°C or wider).

Installation: Plug-in module, mounted on DS200 series motherboard via board-to-board connector or socket.

Importance:

System stability guarantee: ensuring the reliability of the core power supply of the control system is the basis for the safe and stable operation of the whole turbine unit.

Protection function cornerstone: Its feedback signal is the main input source of power failure protection logic (such as TMBF-Turbine Monitor Board Fault). Power problems can trigger protection actions in time to prevent equipment damage.

The key to fault diagnosis: the status indicator on the module and its output signal are the first hand data for diagnosing power related faults.

Common locations and associations:

It is most commonly installed on DS200 TBCI (Terminal Board Control Interface) boards.

It may also be installed on DS200 DAP (Drive Application Processor) board, DS200 LAP (Logic Application Processor) board, DS200 SHMC (Station HMI) board Module Controller) board or other DS200 series I/O/ auxiliary board.

Its status signal eventually reaches the <ICRH> processor board or protection relay logic

GE power board DS200DCFBG1BKC DC feedback module

GE power board DS200DCFBG1BKC DC feedback module

GE power board DS200DCFBG1BKC DC feedback module

You may also want to know about related products:

GE UCSCH1 IS420UCSCH1A controller

GE IS420UCSBHЗ Ethernet switch module

GE 029.38089607 control module